How Optifye.ai is Revolutionizing Manual Assembly with AI Optimization

In the fast-paced world of manufacturing, efficiency is king. Whether it’s boosting productivity, reducing downtime, or minimizing errors, manufacturers are always looking for ways to improve. Enter Optifye.ai, a promising startup that aims to revolutionize manual assembly lines by leveraging cutting-edge AI and computer vision technologies. Founded in 2024 by Vivaan Baid and Kushal Mohta, Optifye.ai is quickly making waves in the industry with its unique approach to optimizing shop-floor operations.

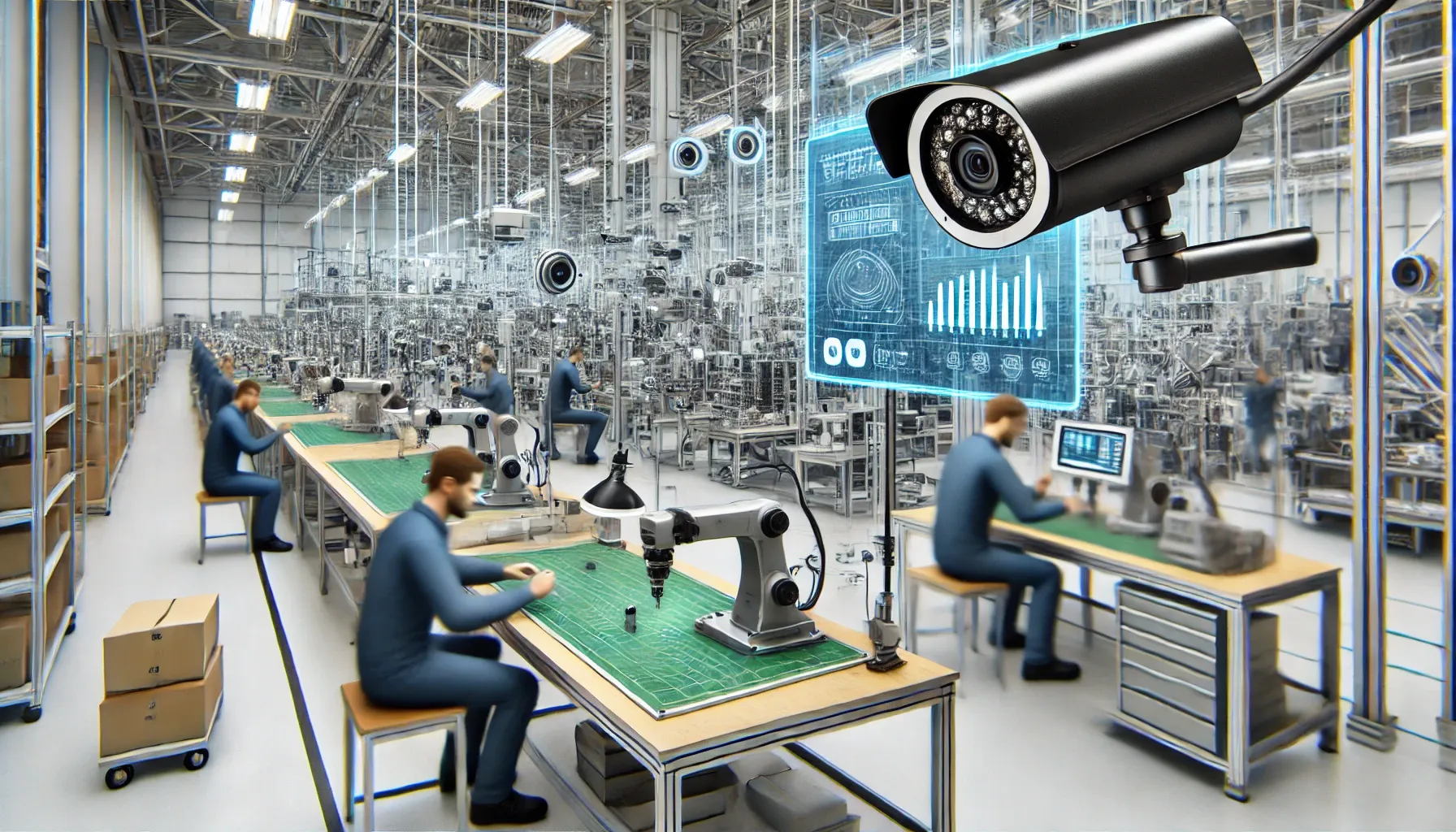

Optifye.ai offers a game-changing solution to the traditional inefficiencies found in manual assembly lines. Using cameras and computer vision algorithms, the system provides real-time data that helps supervisors monitor, manage, and enhance assembly line operations. The goal? To help manufacturing companies increase their line efficiency by up to 30%.

Let’s dive into how Optifye.ai is shaping the future of manufacturing operations and how it can benefit businesses that rely on manual assembly processes.

What Problem Does Optifye.ai Solve in Manufacturing?

Manufacturing companies, particularly those that rely on manual assembly, have long struggled with inefficiencies on the shop floor. These inefficiencies can range from slow production speeds and unbalanced workloads to human errors and inconsistent product quality. Historically, the shop floor has been a "black box" — it’s difficult to accurately measure performance, and managers often lack the visibility to identify and fix problems quickly.

On top of this, supervisors on the shop floor are often responsible for managing over 50 workers. With so many people and processes to keep track of, it’s nearly impossible to catch every inefficiency and resolve issues before they cause delays or defects. Manufacturing companies often rely on production heads to manage the day-to-day performance of lines, but these individuals don’t always have the data they need to make accurate, data-driven decisions.

This is where Optifye.ai steps in. By implementing cameras along the assembly line and using computer vision, Optifye.ai captures real-time data on the number of items produced, the speed of production, and where inefficiencies are occurring. The result is an intelligent system that brings much-needed transparency and control to assembly line operations.

How Does Optifye.ai Work?

At the heart of Optifye.ai is a simple yet powerful concept: if you can measure it, you can improve it. The system places cameras in key areas of the assembly line and uses computer vision to analyze the work being done at each station. This allows Optifye.ai to provide supervisors with precise, real-time information on the productivity of individual workspaces and the overall line.

Here’s a breakdown of how the technology works:

- Camera Installation: Cameras are strategically placed along the assembly line to capture visual data.

- Real-Time Analysis: Computer vision algorithms process the footage to track the number of products being produced, identify bottlenecks, and pinpoint inefficiencies.

- Actionable Insights: Supervisors can access detailed, real-time data on how each workspace is performing. This helps them identify areas that need attention, such as slow production speeds or quality issues.

- Efficiency Boost: With the data and insights provided by Optifye.ai, supervisors and production heads can make informed decisions to resolve issues and optimize the line’s overall efficiency.

By combining computer vision with real-time data analysis, Optifye.ai allows manufacturers to gain unprecedented visibility into their operations. This capability enables them to proactively address inefficiencies and improve their overall production rates.

What Are the Benefits for Different Stakeholders in Manufacturing?

Optifye.ai isn’t just for one stakeholder — it’s designed to benefit everyone involved in the manufacturing process. Whether you’re an owner, a production head, or a shop floor supervisor, Optifye.ai provides tailored insights that align with each role’s specific needs and objectives. Here’s how each key player benefits from the system:

- For Owners: Optifye.ai gives owners accurate, real-time data on factory performance, including detailed metrics on line productivity and workspace output. This eliminates the need for subjective assessments and helps owners get a clear picture of how their operations are performing. With accurate data at their fingertips, owners can make better strategic decisions and ensure that their facilities are running at peak efficiency.

- For Production Heads: Production heads are responsible for overseeing multiple lines and ensuring that production targets are met. Optifye.ai provides line-wise and workspace-wise metrics, enabling production heads to identify areas where efficiency can be improved. With these insights, they can make data-driven decisions on how to optimize the production process, allocate resources, and resolve issues before they impact overall productivity.

- For Shopfloor Supervisors: Shopfloor supervisors are the ones on the ground, directly managing workers and ensuring that production runs smoothly. With Optifye.ai, supervisors finally have access to data that helps them identify inefficiencies in real-time. Whether it's a slowdown at a particular station or an issue with product quality, supervisors can take immediate action to correct the problem, reducing downtime and improving overall line efficiency.

What Makes Optifye.ai Different from Traditional Manufacturing Solutions?

While traditional manufacturing solutions often rely on manual data collection, subjective observations, and reactive decision-making, Optifye.ai offers a proactive, data-driven approach to assembly line optimization. Here’s what sets Optifye.ai apart from other solutions on the market:

- Real-Time Data: Unlike traditional systems that rely on historical data, Optifye.ai provides real-time performance metrics, giving supervisors and managers immediate visibility into how the assembly line is functioning at any given moment.

- AI-Powered Insights: Optifye.ai doesn’t just collect data — it uses AI to process that data and provide actionable insights. This allows manufacturers to not only track performance but also predict and resolve inefficiencies before they become major problems.

- Computer Vision: Optifye.ai uses computer vision to monitor the production process at a granular level. This provides a level of detail and accuracy that traditional manual tracking methods can’t match.

- Scalability: Optifye.ai can be implemented in any manual assembly line, regardless of size or complexity. Whether a small facility or a large manufacturing plant, Optifye.ai’s system is scalable and adaptable to a variety of environments.

What Are the Future Prospects for Optifye.ai?

As the manufacturing industry increasingly turns to automation and smart technologies, the future looks bright for Optifye.ai. The ability to enhance line efficiency by up to 30% is a significant selling point, and with manufacturing companies constantly looking for ways to stay competitive, solutions like Optifye.ai are in high demand.

The team behind Optifye.ai — Vivaan Baid and Kushal Mohta — both have strong backgrounds in computer science, psychology, and engineering, as well as hands-on experience in the manufacturing world. This unique combination of technical expertise and practical insight positions Optifye.ai for success as it continues to grow and expand its impact.

Optifye.ai’s system is likely to evolve as well. As AI and computer vision technologies improve, we can expect even more advanced features, such as predictive analytics, enhanced automation, and better integration with existing manufacturing software. As it stands, the company’s commitment to improving real-time decision-making on the shop floor makes it an exciting startup to watch.

Conclusion: Why Optifye.ai Matters for the Future of Manufacturing

In an industry where efficiency can make or break a company, Optifye.ai’s AI-powered line optimization system offers a powerful tool for manufacturers seeking to maximize productivity and streamline operations. By leveraging computer vision and real-time data analysis, Optifye.ai provides actionable insights that help every stakeholder on the shop floor — from owners to supervisors — make better decisions and boost line efficiency.

As Optifye.ai continues to grow, it has the potential to reshape how manufacturers approach efficiency, helping them stay competitive in an ever-evolving market. With its blend of innovation and practical insight, Optifye.ai is a startup to watch in the world of manufacturing technology.