The Hidden Power Behind Electric Vehicles: Meet Steinmetz

Founded in 2024 in San Francisco by former Tesla engineers Owen Brake and Ethan Childerhose, Steinmetz is not just another EV startup—it’s a hardware-first platform company on a mission to revolutionize the electric vehicle industry from within. While many companies focus on battery innovation, vehicle design, or software enhancements, Steinmetz dives straight into the power electronics—the beating heart of an electric vehicle’s propulsion system.

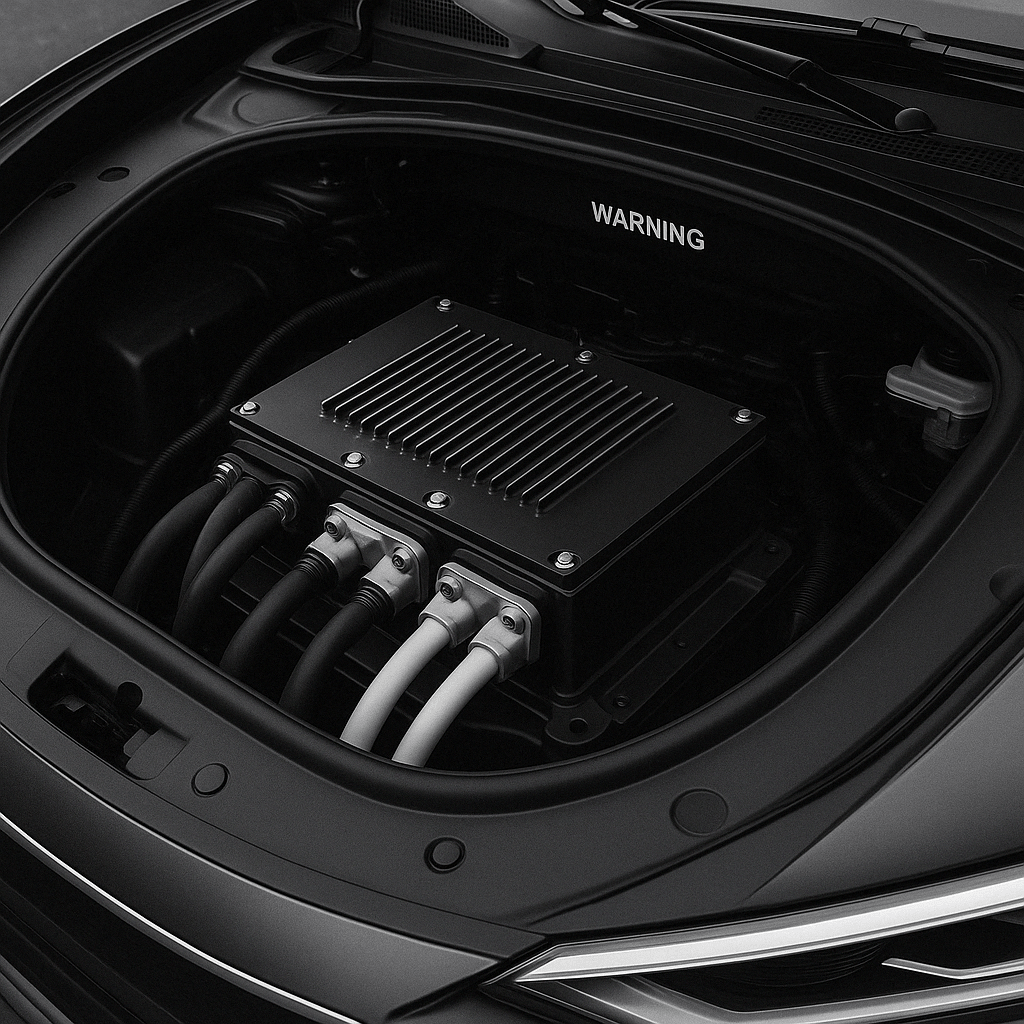

At its core, Steinmetz is tackling one of the biggest bottlenecks in EV manufacturing: the inverter, also known as the motor controller. This device is responsible for converting the direct current (DC) from an EV's battery into three-phase alternating current (AC) that powers the motor. By optimizing this crucial but often overlooked component, Steinmetz is reshaping what’s possible in terms of power density, efficiency, and cost.

Why Are Current Electric Vehicle Systems Inefficient and Expensive?

The transition from combustion engines to electric drivetrains is happening, but too slowly. Despite global regulatory pressure and increasing environmental awareness, EV adoption still trails behind expectations. A primary reason? Cost and performance.

Most traditional car manufacturers are racing to electrify their fleets but are doing so using legacy supply chains and partners, suppliers who are masters of mechanical engineering but often lack expertise in electrical systems, especially power electronics. As a result, the EVs they produce tend to be:

- Bulky in design

- Expensive to manufacture

- Lower in performance compared to pioneers like Tesla

Having worked directly at Tesla, Owen and Ethan saw this technological chasm firsthand. Tesla’s in-house capabilities in power electronics gave it a monumental edge in designing leaner, faster, and more efficient EVs. Steinmetz aims to bring that level of expertise to every other automaker by becoming the go-to provider for next-generation inverters.

How Does Steinmetz Redefine the Role of the Inverter in EVs?

Most people don't realize how critical the inverter is to the performance and cost of an EV. As the bridge between the battery and the motor, it's responsible for managing how power flows, affecting everything from acceleration to thermal performance.

Steinmetz’s breakthrough lies in their ability to increase power density by 3x compared to the state of the art, without raising costs. That means more power per kilogram and liter, all while reducing overall vehicle weight and complexity.

To put this in perspective, their bandgap inverter can handle 200kW of peak power in a volume equivalent to three yerba mate cans. That’s the same energy output as 450 NVIDIA RTX 4090 GPUs or 6.5 server racks filled with NVIDIA H100 GPUs—crammed into a space you could hold in your hand.

But the benefits go beyond performance specs:

- Lower system costs for automakers

- Better vehicle range due to improved efficiency

- Simpler thermal and mechanical integration

The knock-on effect is massive: more affordable and better-performing EVs for end consumers.

What Are Power Density and System Efficiency—and Why Do They Matter?

In the world of power electronics, power density is measured in kilowatts per kilogram (kW/kg) or kilowatts per liter (kW/L). It's a metric that tells you how much power a device can process relative to its size or weight.

Higher power density means:

- Less space needed for the component

- Lower weight, which improves vehicle efficiency

- More room for other features or smaller vehicle frames

Efficiency, on the other hand, determines how much of the energy from the battery is converted into usable power for the motor. The higher the efficiency, the less energy is wasted as heat, which again contributes to better range and performance.

Steinmetz’s inverters hit the sweet spot by:

- Delivering top-tier efficiency and density

- Reducing heat generation, which simplifies cooling systems

- Enabling tighter integration with other vehicle systems

These advantages add up to what Steinmetz calls “system-level wins,” meaning the benefits cascade throughout the entire vehicle architecture.

How Does Steinmetz Stay Cost-Competitive Despite Cutting-Edge Performance?

You might expect that tripling power density would come at a steep price. But cost efficiency is built into Steinmetz’s DNA.

By utilizing modern power electronics techniques—especially involving wide bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN)—the company achieves high performance without exotic or proprietary materials. Their approach prioritizes tight system integration, meaning every component is optimized to work seamlessly with the others, avoiding redundancy and saving on material costs.

Their goal isn’t just to make the best inverter—it’s to make it affordable and accessible to all automakers looking to compete in the EV market. In fact, Steinmetz’s founders believe cost parity with today’s leading inverters is crucial to enable large-scale adoption.

Who Are the Founders Behind Steinmetz, and What Drives Them?

Steinmetz was founded by Owen Brake and Ethan Childerhose, two engineers who gained deep insight into the EV world through their work at Tesla. There, they saw firsthand how much power electronics innovation contributed to Tesla's lead in the industry.

They also saw how traditional car manufacturers, despite deep experience in combustion engine design, struggled to keep up due to their lack of electrical engineering depth. That gap became the opportunity that Steinmetz was born to fill.

Named after Charles Proteus Steinmetz, a legendary figure in the early days of electrical engineering, the company embraces a legacy of precision, innovation, and systemic thinking. Ethan and Owen are not just building components; they’re engineering a new standard for the next generation of EV platforms.

What’s Next for Steinmetz and the EV Industry?

The inverter is just the beginning.

Steinmetz is positioning itself as a platform company—one that will expand into other areas of the EV hardware stack over time. Their long-term vision includes:

- Developing modular hardware systems for EV manufacturers

- Driving standardization across core EV components

- Supporting OEMs and startups with ready-to-integrate, high-performance hardware

Their mission is bold but simple: Accelerate the global adoption of electric vehicles by making the hardware radically better.

And by focusing on what others have overlooked—the invisible engines inside the electric revolution—Steinmetz might just become one of the most important enablers of mass EV adoption in the coming decade.

How Is Steinmetz Shaping the Electric Future?

As the world races toward an all-electric future, one thing is clear: hardware matters.

While batteries and software get most of the attention, the power electronics, especially components like inverters, are what determine whether electric vehicles can be both high-performing and widely affordable.

By radically improving this core component, Steinmetz isn’t just boosting the power of individual vehicles—it’s lowering barriers across the entire EV ecosystem.

Their contribution may not always be visible to the end consumer, but make no mistake: the EV revolution won’t run without companies like Steinmetz building the hardware that makes it possible.